Wrought Iron | Hand-Forging Twists And Spirals

Wrought Iron | Hand-Forging Twists And Spirals

Wrought Iron : Hand-Forging Twists And Spirals

To give interest to square and flat bars of wrought iron, twisting and creating spirals can add an aesthetically pleasing appearance to an otherwise plain railing, set of fireplace tools, or even a hook.

Twisting a Wrought Iron Bar

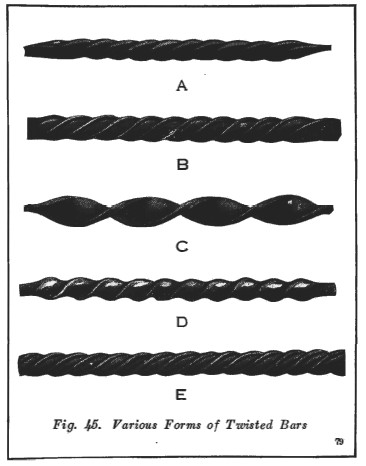

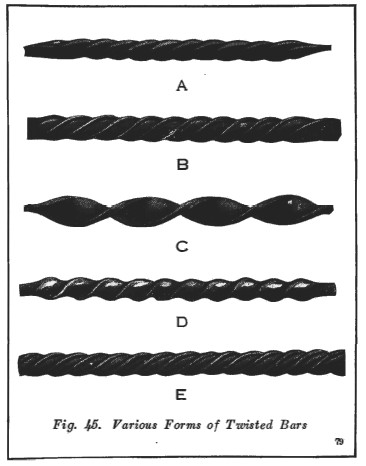

Requires an understanding of the proper techniques of hand-forging wrought iron and an experienced, trained eye in order to determine the proper spacing of the twists. They should be of uniform distance apart in order to be accurate and appear correct. There are many shapes of wrought iron that may be twisted, such as square, flat and hexagon, and although a single round bar cannot be manipulated to create a decent twist shape, two or more twisted together can make a variant on a twist called a spiral.In twisting there are two methods. Flat bars that are not too heavy may be twisted while cold, providing that the stock is of the same thickness throughout its length. If the metal is swelled or tapered due to previous heating or working it must be twisted while hot. The operation of twisting while the iron is hot is very simple. For example, a square bar that measures 10 inches long and 2 inches in diameter that you want to have the twist go the entire length, should be cut about 11 inches long allowing for enough of the bar to be mounted in a vise and after it is twisted it is cut off. The bar is heated in a forge to a 'yellow' color, and this coloring needs to be uniform. The temperature must not exceed 2900 degrees which would be the amount of heat needed to weld. Doing so would destroy the texture of the wrought iron. The bar is heated and twisted to the right using a wrench on the opposite end of the bar that is in the vise.If any part of the bar begins twisting faster or more than another, a stream of water is poured onto the area that is twisting too quickly. In case one part of the bar becomes twisted more what than is desired, it may be remedied by re-heating it, cooling each side with water; and then twisting it back to the desired shape.

Forming A Wrought Iron Spiral

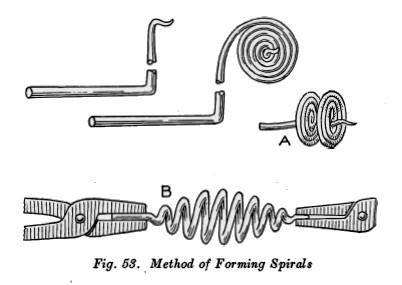

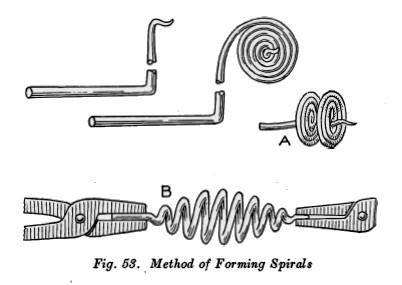

The main thing in working with spirals is to have the twists true and uniform in spacing. In forming a spiral a piece of round wrought iron is first heated on one end, and a considerable part of its length is 'drawn-out' with a hammer giving it a long taper to a point. (Drawing-Out is defined as the process of lengthening the metal). Once the length of wrought iron required for the spiral is determined, it is then measured from the point along the bar, bending it at right angles. About an inch of the point is also bent at right angles. The part of the bar that is to be formed into a spiral shape is heated. Starting at the end, it is 'rolled up' by striking it with the hand hammer until one-half of the bar is coiled. The other half of the bar is now heated, and starting at the corner of the bend, the rest of the bar is rolled into a coil until it overlaps the first coil. At this point the entire piece is heated, holding the point and the stem with a pair of tongs. The coils can be seen as a number of spindle-shaped spiral twists made from round stock and formed by hand with the aid of the hammer and anvil. Spirals of this kind are to adorn ornamental grillwork, as finials, or as tendrils employed in some foliage-style designs.

Share: